If a regular socket wrench doesn't meet your needs, you can step up to hydraulic torque wrench, or a power torque wrench. These two are made by Hytorc wrench, a very reputed manufacturer. They're those that I have already been using for years, but I'm planning to generalize and speak from what each type one of these power tools is for.

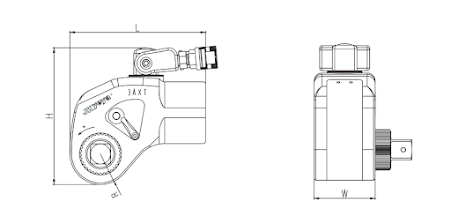

First I will start with the basics. A hydraulic torque is made to exert torque on some type of fastener. The target can be to quickly and securely fasten or loosen various nuts. They apply an number of torque to a lubricated fastener beyond just what a human could muster, usually in conjunction with an impact socket. They certainly were first introduced in the 1960's, but have evolved considerably since that time as a result of manufacturers constantly updating and advancing their designs. It has cause the modern hydraulic torque wrench, one which is light as a result of exotic alloys, having an inferior nose radius to improve the number of spaces it'll squeeze into, possessing multi-position reaction members, and you may even now run multiple tools off of just one power pack simultaneously. Today's modern torque wrenches are optimized for efficiency and flexibility inside their uses.

Why is a hydraulic torque wrench work is so it generates torque using only hydraulic means, it is self ratcheting, and it must have an accurate way to measure the amount of torque put on the fastener. A holding pawl design is popular amongst most manufacturers to lock the wrench in place, but each involve some claim that there design is superior. I say whichever one works, works. These wrenches normally have an accuracy rating of +/- 3%, with a higher repeatability rate. This makes them suited to large bolts that need a higher amount of accuracy. The greatest advantageous asset of a hydraulic wrench doesn't have anything regarding performance, but with those who utilize them - these torque wrenches are significantly quieter than similar output pneumatic impact wrenches. That's good results that you can't measure in strength, repeatability, or work output increases - it is all about the healthiness of those who use it.

An electrical torque wrench is just a gearbox that is attached to a power motor. This gearbox is made in such a way so it absorbs the torque, allowing an individual to operate the wrench with minimal effort. They are typically used if you have no dependence on torque strength accuracy being used on the nut or bolt, or when a very stubborn nut must be removed. The gearboxes can be of ratios as high as 4000:1. and this is adjusted by controlling the voltage. Due to the fact it is powered by electricity, you can find waterproof models for when water is just a concern on the jobsite. It is often confused with an impact wrench because of its similar design, however it is certainly a completely different tool, and is a lot more distinctive from a hydraulic torque wrench. Everything comes right down to the task and getting the proper tool for it.

Different Types Of Torque Wrenches

So you're trying to find out about various kinds of tools and you've recently learn about torque wrenches and are enthusiastic about researching different types?

You've arrive at the proper place!

As you probably know if you're reading this informative article, a torque wrench is a kind of wrench designed to apply torque (force around an axis) to a bolt or nut. Torque wrenches are distinguished from other types of wrenches simply because they have the ability to measure and/or control the amount of force that is applied allowing the appropriate total be utilized and ensuring that the bolt or nut is neither too loose nor too tight.

Let's start with the most simple designs and work out way up.

An easy torque wrench is normally merely a long wrench with an analog needle on it. When the wrench tightens a bolt, the needle will move and point to the worthiness representing the amount of force getting used (for example, 50 pounds of force). These will occasionally must be calibrated, and because the needle is usually exposed it could be bent or moved accidentally and no longer point to the correct value.

There's also electronic torque wrenches that work basically exactly the same, except rather than an analog gauge they have an electronic display. The benefit to this is that it could be easier to see because the worthiness is shown in numbers along with being easier to see with less light (assuming it is bright or runs on the backlit display) such as for instance if you're working behind a big bit of machinery that is blocking the light.

You can find torque wrenches which can be set to a specific degree of force that may stop applying force once that level is reached to simply help prevent over-tightening. With this kind you don't have to concentrate the maximum amount of on the gauge because it'll stop tightening at the correct force.

Hydraulic torque wrenches use hydraulics to tighten or loosen a fan or bolt. This type of wrench runs on the predetermined number of torque and can operate more quietly than similar pneumatic wrenches, and undoubtedly many individuals feel hydraulic wrenches really are a better choice due to the precise nature associated with tightening bolts.

What Are Torque Wrenches? What Do They Do?

If you've ever loosened lug nuts on car to take the wheels off or tightened them after putting the wheels on, you've probably used a torque wrench. Well, let me rephrase; if you've ever put the lug nuts back on an automobile, hopefully you used a torque wrench.

A torque wrench is just a wrench made to allow you to tighten nuts or bolts without over-tightening them, that is prevented in a variety of ways.

Lets return to the lug nuts. If the lug nuts on your car must be tightened to 75 foot pounds you will need to ensure you have a way of knowing when you've reached 75 foot pounds. Are you just going to employ a regular wrench and guess?

That's why I said above that "hopefully" you used a torque wrench. A standard torque wrench may have a measure on it that shows you how much force you are applying. As you tighten the nuts the needle will point to the amount of force getting used that will allow you to apply the right amount.

Most wrenches of this kind are fairly long allowing sufficient leverage to generate enough force. If you're tightening your lug nuts with a 16" wrench you're going to have a much simpler time than if you test it with a 10" wrench, for example.

Although some types of these wrenches just have a measure to inform you how much force you're applying, others already have mechanisms that stop you from applying a lot of force. Like, some wrenches have a clutch that disengages when the correct number of force is applied so that you cannot tighten the bolt any further.

Now, what if you're working with bolts that are bigger compared to the lug nuts that hold your wheels on? What if you need to tighten something to 10,000 feet pounds rather than 100? In these cases there is a different type of wrench, a hydraulic torque wrench, that uses hydraulic power to apply the necessary force to the bolts. Hydraulic torque wrenches have been with us because the mid-60's but recent improvements inside their design have made them smaller, lighter, and and more easily able to match into tight spaces. This type is considered a lot better than pneumatic wrenches because they are quieter, lighter, and more accurate.

How A Pneumatic Impact Wrench Works

A pneumatic impact wrench or air gun is an invaluable tool for removing stubborn nuts and bolts. It runs on the strong jerking motion to simply help free fasteners that were over tightened or which have rusted over time. Compared to a traditional wrench, this can be quite a real improvement, and will make difficult jobs far easier. There's a wide range of various kinds of impact wrench out there, pneumatic being just one of them. In this informative article, we will look at the alternatives and their relative merits along with explain the function of the impactor generally.

How an Air Gun Works

An air gun differs from other powered wrenches in so it delivers its torque in instantaneous jolts rather than with a regular force. Essentially, the inner motor spins a rotating mass, which then hits the output shaft. This repetitive impact results in the rattling noise and also in the effectiveness of the wrench. The countless minor impacts work to cut back the torque felt by an individual while greatly increasing the instantaneous torque put on the nut or bolt. Multiple short, sharp applications of torque can remove even probably the most stubborn fastener, even one that has rusted severely. Models typically differ in both their torque and their weight, all of which make a positive change to the tool's usability.

Different Varieties

A pneumatic impact wrench has several competitors in the form of different drive mechanisms. Hydraulic impact wrenches are utilized in some industrial applications where pressured hydraulics are available, but electric impact wrenches are more popular among home users. It is even possible to have cordless electric variants, although these are typically down on power compared for their more heavy-duty brethren. The sort chosen will depend on the context and circumstances; a hobbyist who needs a portable powered wrench will probably prefer a cordless electric version, while much more serious professional use will probably require the stronger pneumatic option.

Conclusion

A pneumatic impact wrench is a good choice for removing difficult nuts or bolts. There are a few alternatives, such as the cordless electric variant, that might are better for some people, but for sheer power and performance, it is hard to beat compressed air. Check out the torque and weight of the air gun to find out its suitability. There's no sense in buying a wrench with either not as or vastly greater torque than you require, and a heavy model will cause you some discomfort when useful for long periods.